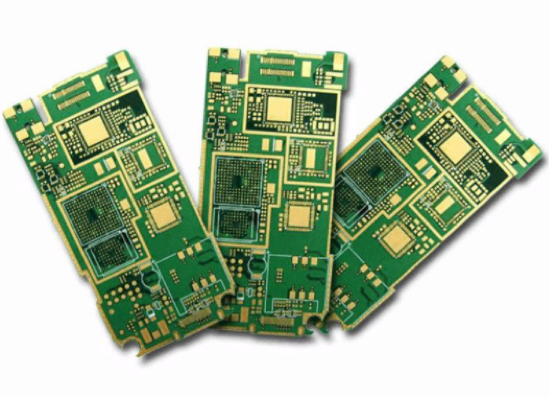

Professional PCBA Electronics Manufacturing Service provider

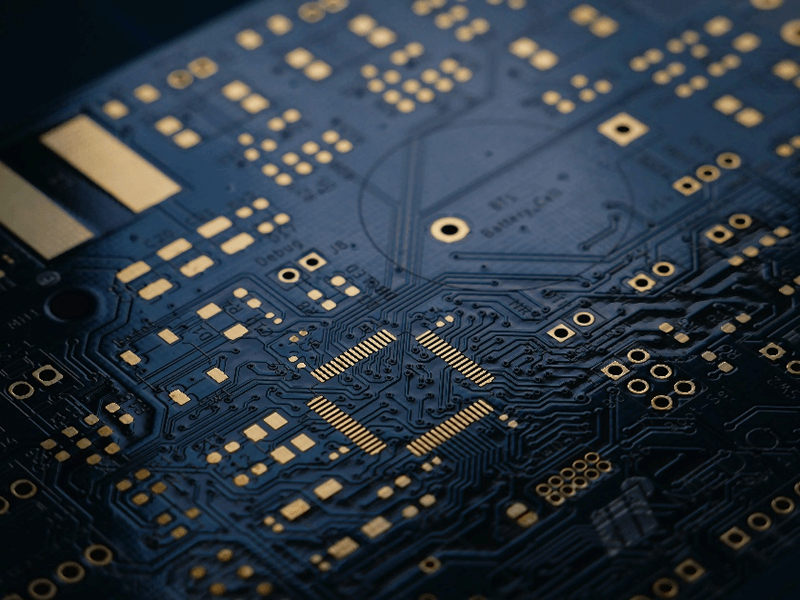

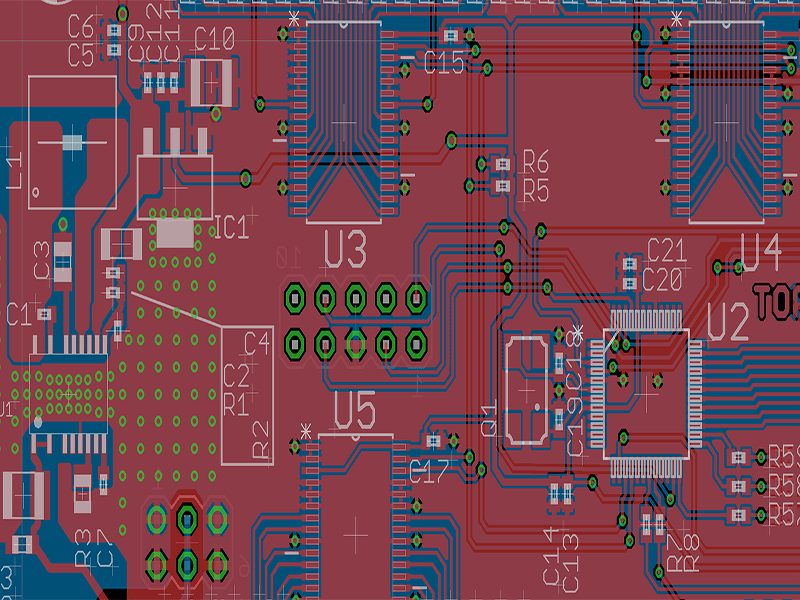

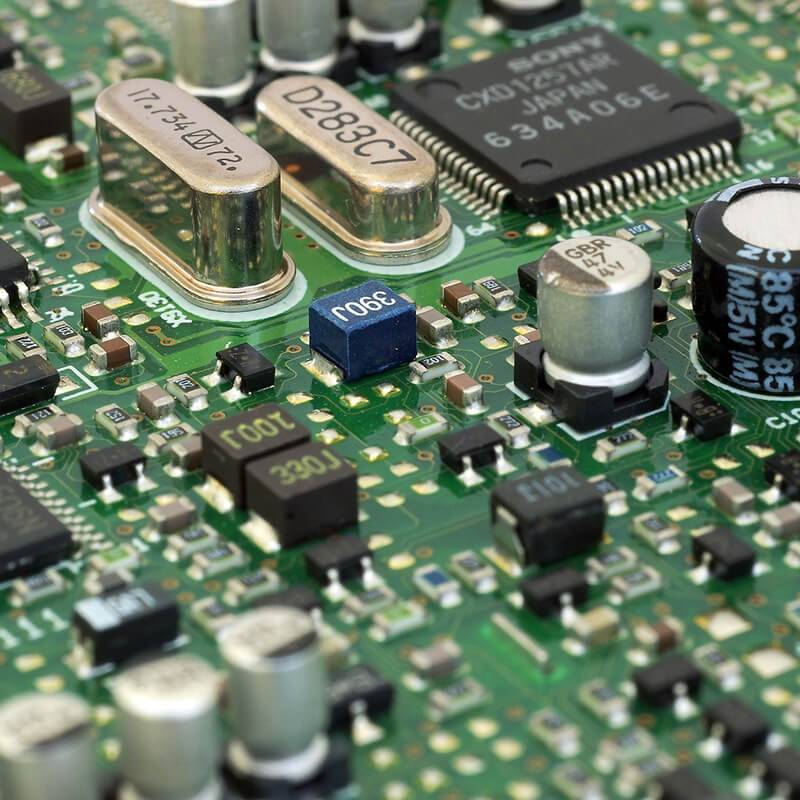

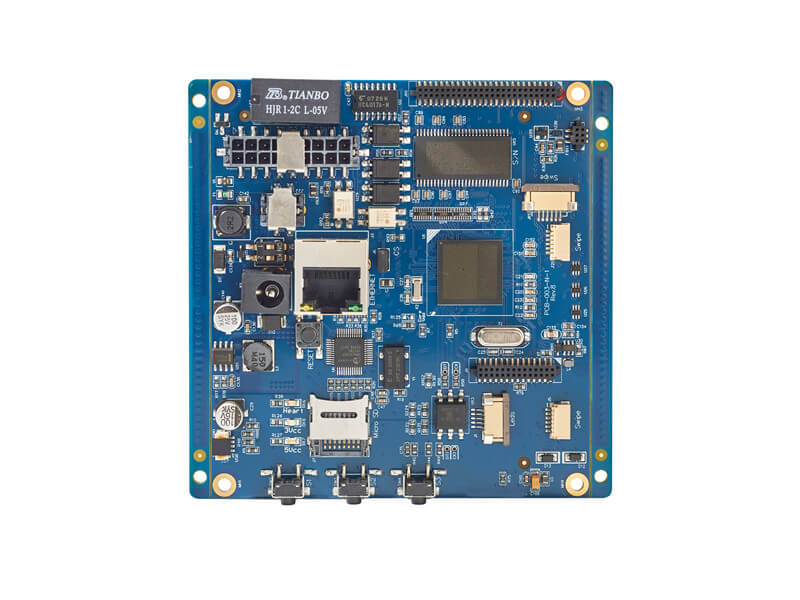

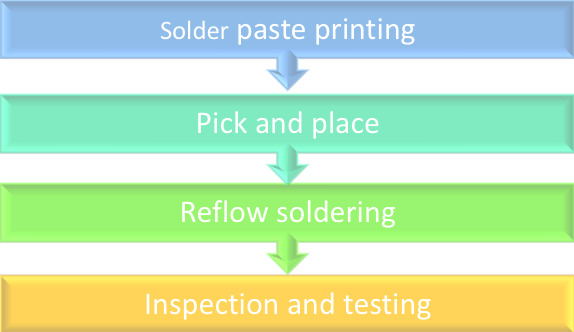

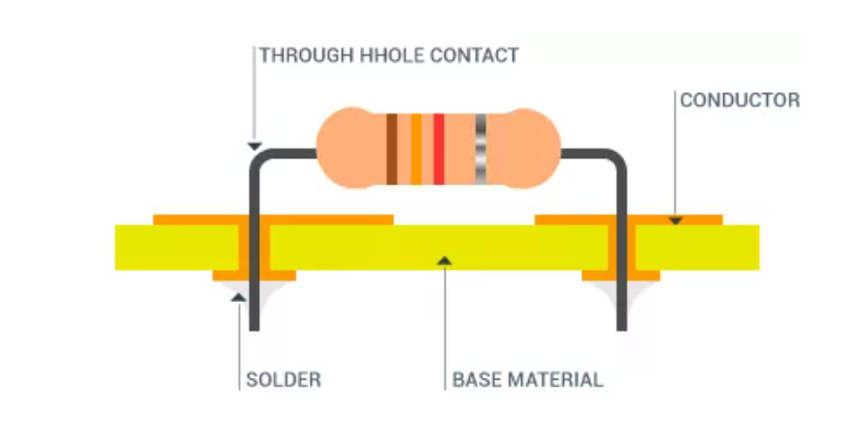

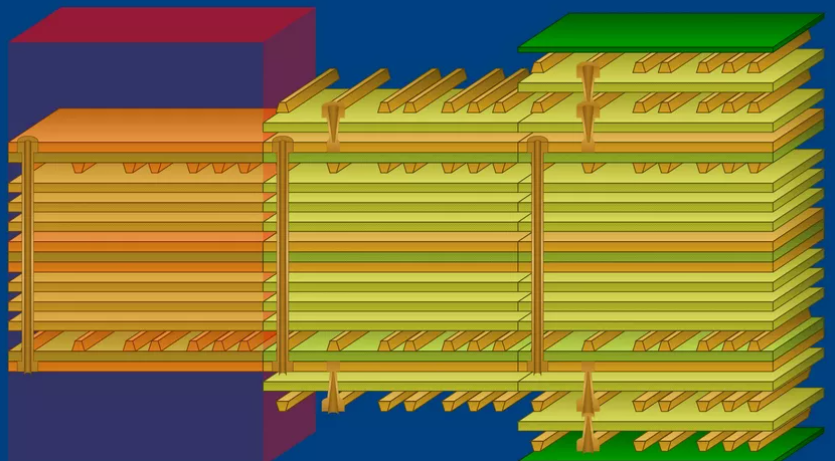

As a China pcba manufacturer, UET PCBA was founded in 2005, based in Shenzhen, China. We have a modern standard pcb board assembly factory more than 4,000 square meters. As a professional PCB/PCBA manufacturer in China, we provide a full range of pcba electronics manufacturing services from PCB fabrication, PCB assembly to OEM/ODM, including PCB design, PCB layout, rapid PCBA prototyping. Besides, components procurement, SMT/ THT assembly, PCBA testing, China pcb prototype, China pcb assembly services and box build assembly are also the part of our business.

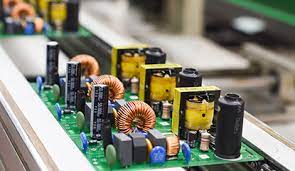

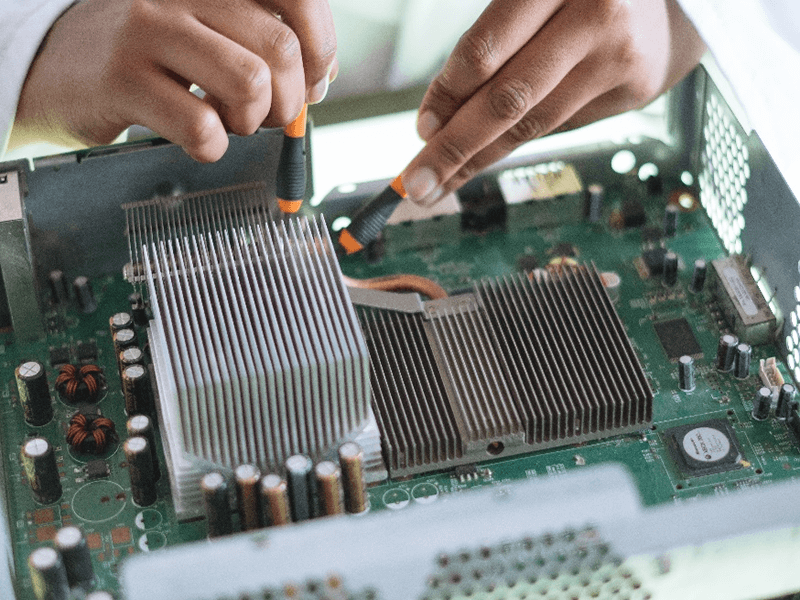

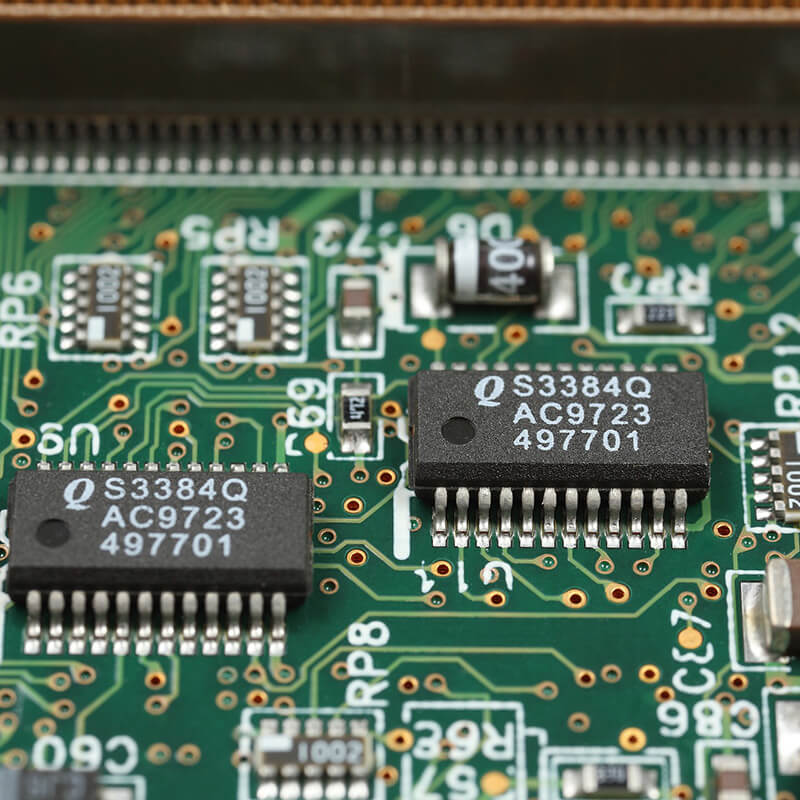

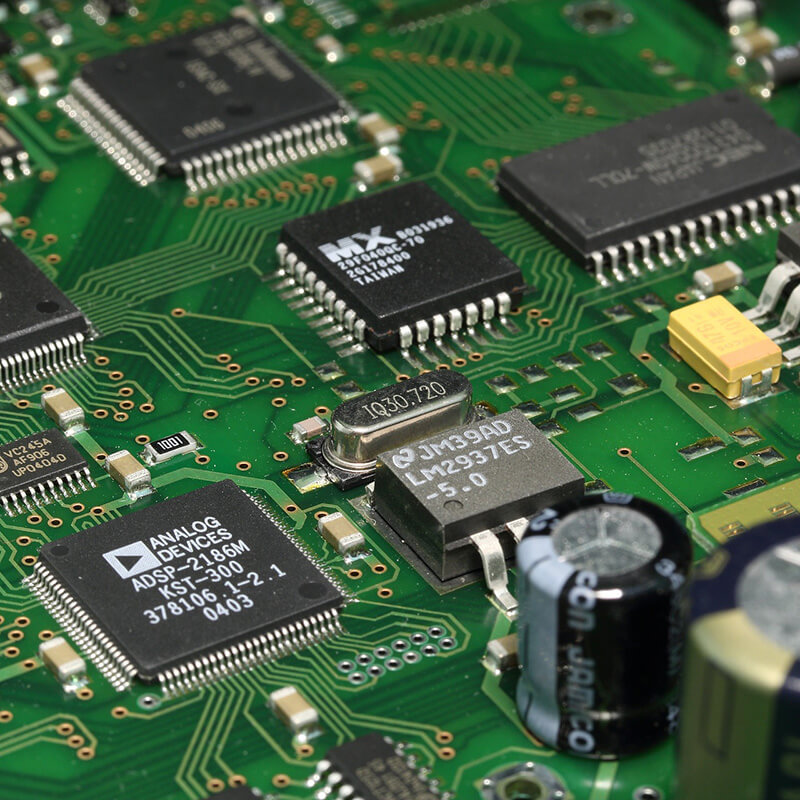

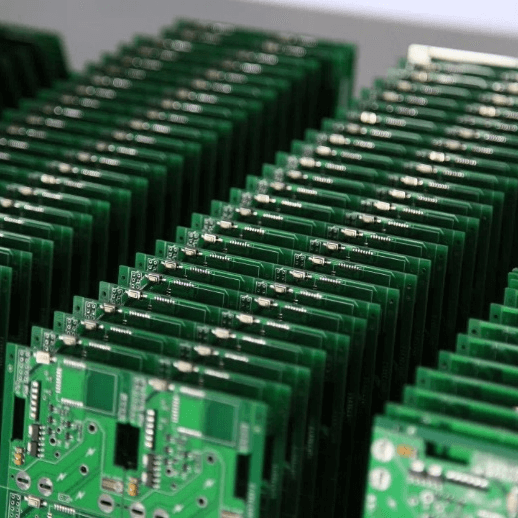

We produce the best pcb in china. We have advanced pcba manufacturing equipment and leading technology with 8 fully automatic high speed SMT production lines, 4 DIP plug-in production lines, 2 ICT/FCT test lines and 4 Box-build assembly lines. UET PCBA has the best pcb manufacturing in China.We have been passed ISO9001, ISO13485 medical quality management certification, UL certification, IATF16949 automotive quality management certification, and implemented IPC-A-610E Class II electronic acceptance standard. What’s more, we have an excellent 300+engineering & production team and an experienced component procurement team. To provide high quality China PCBA board to customers is our ultimate goal.

As a China pcb assembly company, we offer a wide range of pcba electronics to customers from different countries. At the same time, we dedicate ourselves to providing customers with one-stop PCBA solutions in different fields. Nowadays, Many application industries, such as Automotive, Medical, Consumer Electronics, Aerospace, Digital Communications, Industrial Control, Smart Home, IoT (Internet of things) choose our pcb board assembly services.

.png)