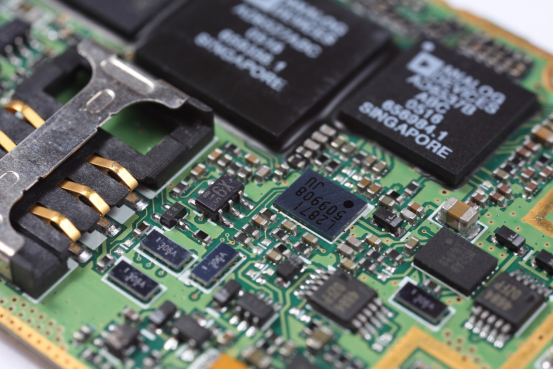

Surface Mount Technology (SMT) PCB Assembly

Surface Mount Technology smt pcb assembly is the most commonly used technology in the electronic manufacturing industry. The surface mount technology smt pcb assembly offer consistent performance for a long time in high-speed circuits.

As a an experienced and fast turnaround smt manufacturer, UETPCBA provides smt manufacturing services, including high-end smt pcb assembly, rapid smt assembly and turnkey solutions for PCB assembly to customers in a wide range of industries. With our full-service of fabrication from high-quality SMT PCB assembly to fast 24 hours delivery times, we continuously improve our SMT assembly services and smt surface mount technology to meet complex customer requirements. When you work with us, you can trust our customer-centric service philosophy, ready to provide you with professional technical support and perfect quality of products.

We use manual and automatic smt pcb manufacturing process for prototype PCB assembly and small-batch PCB production. Equipped with 8 automatic high-speed SMT lines, automatic smt soldering paste printer, SPI of solder paste thickness tester, multiple temperature zones reflow soldering, AOI optical inspection equipment, X-Ray inspection equipment, stencil cleaning machine, such as long-term for clients with smt PCB assembly services.

The Applications of SMT Manufacturing

With its characteristics and advantages,SMT manufacturing has made a fundamental and revolutionary change in electronic assembly technology.SMT soldering service has grown very rapidly in the last 10 years, a very wide range of applications, has been permeated to various fields, such as smart home industry, power industry, network communication industry, military industry, automotive electronics industry, industrial control, medical electronics industry, security industry, etc.), And in many fields has partially or completely replaced the traditional through-hole technology.

The Advantages of the SMT Manufacturing

(1) High assembly density, small size, and lightweight of electronic components/products.

(2) High reliability, strong anti-vibration ability, and low solder joint defect rate.

(3) Good high-frequency characteristics, reduce electromagnetic and radio frequency interference.

(4) easy to achieve automation and improve production efficiency.

(5) Reduce the production cost of materials, equipment, manpower, time, etc.

UETPCBA’s Rapid SMT Assembly Service

Who We Are?

(1) Intelligent SMT soldering factory

(2) Equipped with 8 fully automatic SMT lines

(3) Provide online AOI, Xray, 3D SPI and other test instruments

(4) Provide OEM rapid SMT assembly service

Why Us?

(1) Perfect inspection equipment and advanced SMT lines to control the quality of the SMT soldering

(2) Twelve temperature zone reflow oven to control soldering quality.

(3) Having high smt surface mount technology. Strictly implement IPC-A-610 standard to control PCBA quality

Capabilities of SMT PCB Assembly

- Single sided/Double sided

- Ball Grid Array (BGA)

- Ultra-fine Ball Grid Array (uBGA)

- Quad Flat Pack No-Lead (QFN)

- Quad Flat Package (QFP)

- Package-On-Package (PoP)

- Small Outline Integrated Circuit (SOIC)

- Plastic Leaded Chip Carrier (PLCC)

- Chip-scale Package (CSP)

- 0201 components

- Fine Pitch 0.2 mm

- 0.4mm Pitch BGA

- Other precision electronic components.