According to customers’ requirements from product concept, design to production, we are committed to providing customers around the world with one-stop product development solutions, winning the trust of customers with very competitive prices and quality services.

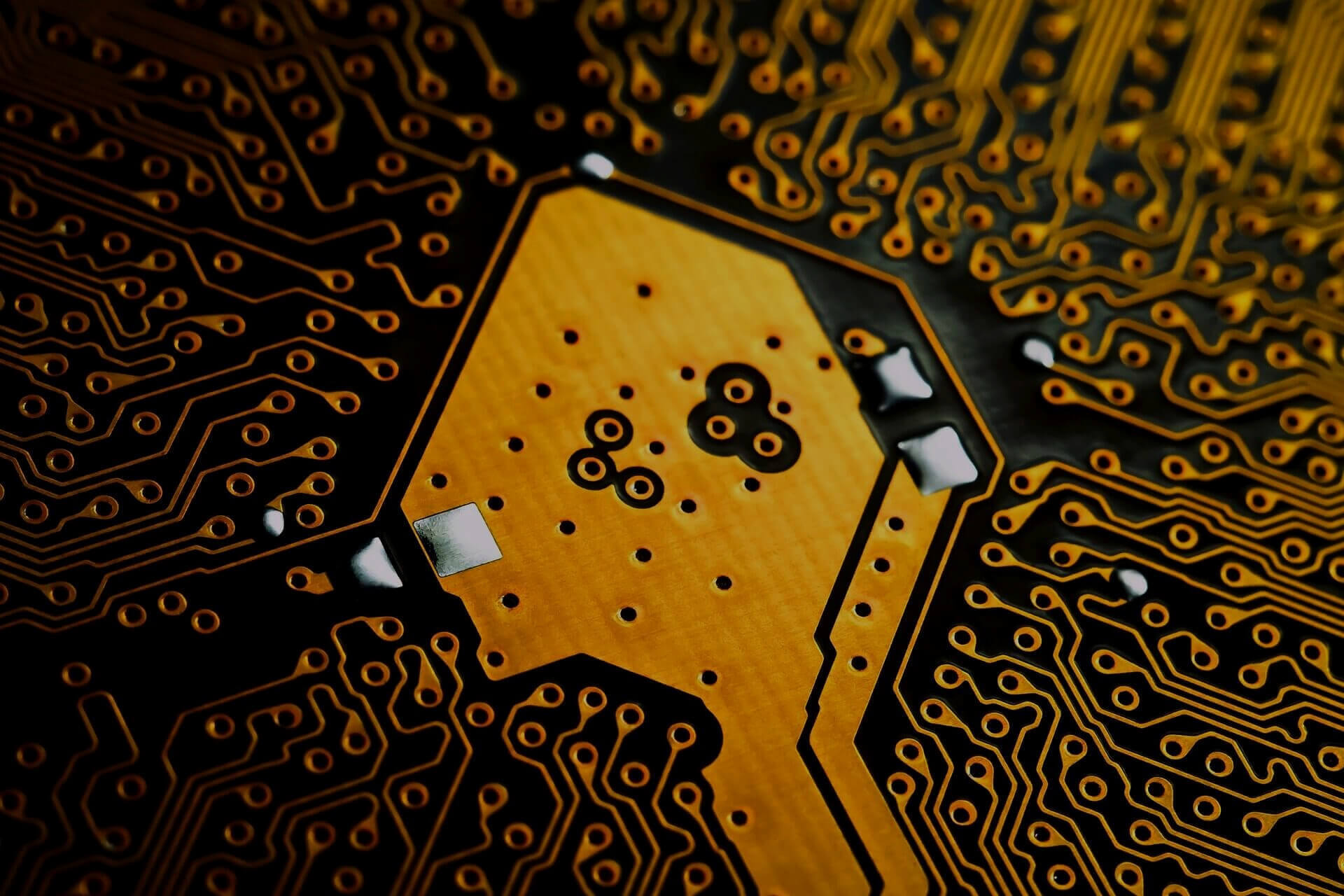

Our comprehensive PCB design services capabilities ensure a completed understanding of your project’s technical requirements and DFM ((Design for Manufacturability). Our PCB designs conform to the IPC 2200 standard and PCB assembly to IPC-A-610 standards.