What Is Rapid PCB Prototyping?

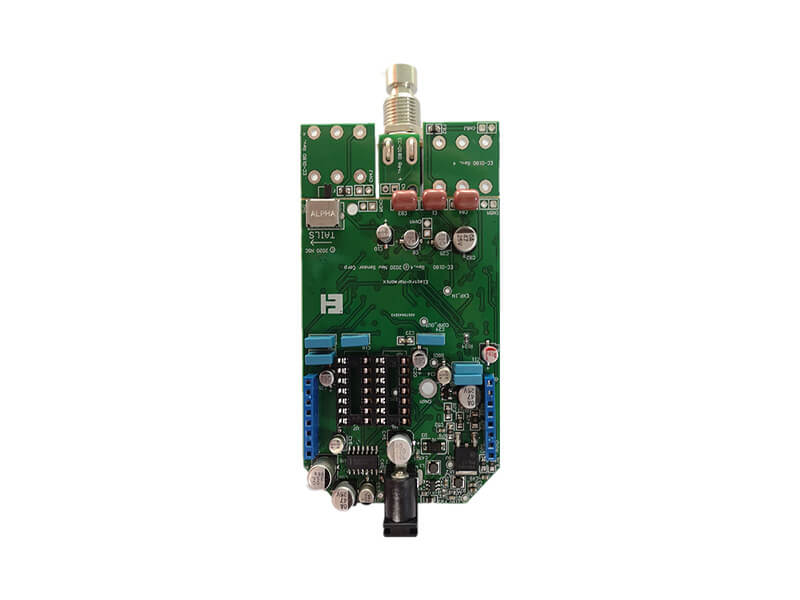

There are many development and test cycles from PCB prototyping to marketing, of which rapid PCB prototyping is very important. The primary purpose of rapid PCB prototyping is to test and ensure that the design meets the functional requirements of the project and can be used to validate your final product.

Rapid PCB prototyping is the pre-production of printed circuit boards before mass production, usually requiring PCB prototype manufacturers to quickly produce 5 to 100 pieces to help speed up the design and testing process. It is mainly used for electronic engineers to deliver the designed PCB files and BOM to the manufacturer after they have completed the circuit board. It needs to be analyzed from multiple perspectives to ensure that there is no delay in the project cycle and reduce the risk of product release.

What Are the Benefits of A Rapid PCB Prototyping?

Fast turnaround

Rapid PCB prototyping services provide a fast turnaround that minimizes the time required to create a PCB prototype, thereby reducing the design and testing phases of PCB development and allowing the final product to reach the market as quickly as possible.

Product testing

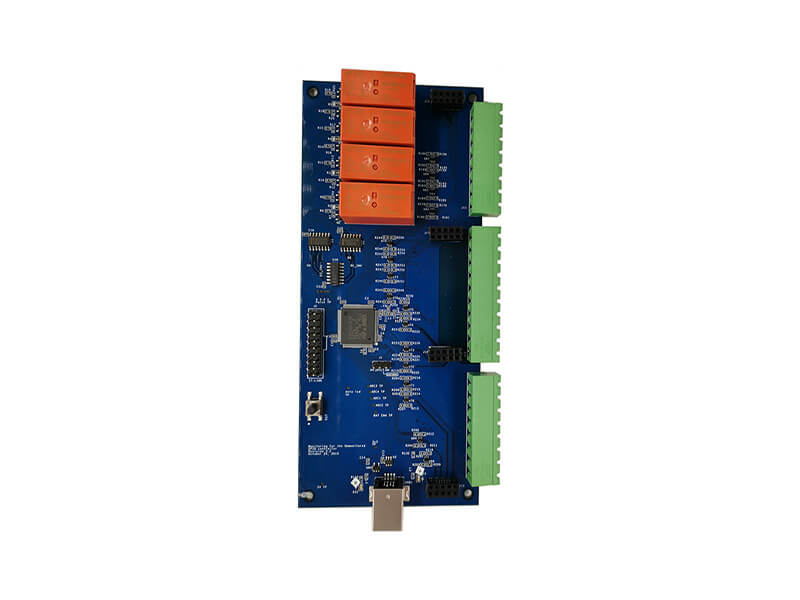

Rapid PCB prototyping allows designers to accurately test each circuit design and function, and ensures that you don’t have to face costly errors when starting mass production. Accurately rapid PCB prototyping helps designers find problems and make modifications.

Modification flexibility

After the PCBA prototype is obtained, designers can modify and optimize the design according to the shortcomings or defects of the prototype. Before mass production, they can modify the design more flexibly and have more time to verify the function of the product and adjust it in time.

Cost reduction

Rapid PCBA prototyping service can produce a small number of prototype boards for testing, and after the PCBA prototyping can ensure that the subsequent production and processing smooth, the factory can be arranged and scheduled according to the PCBA prototyping process, so it can effectively eliminate the waste of human resources and material resources waste.

How to provide documents for rapid PCB prototyping

What should be noticed in the rapid pcb prototyping documentation?

- File format: Normally need to provide Altium/Gerber/Eagle files. For the Gerber file, (for now we only accept RS-274-X format), double layers are shown below:

GTL- top copper layer

GBL- bottom copper layer

GTS- top solder mask layer

GBS- bottom solder mask layer

GTO- top overlay layer

GBO- bottom overlay layer

DRL -drill layer

GM1- mechanical 1

GKO- keep-out layer

4 layers need the extra layer order, eg:

TOP-VCC-GND-BOT 、TOP-GP1-GP2-BOT、 TOP-G1-G2-BOT、 art001-art002-art003-art004

- PCB parameters: there are general the number of layers, material, thickness, surface finish, color of solder mask, copper thickness, and other specific requirements, the following to understand the main parameters of this part.

Materials:It is best to consult in advance to explain what kind of materials are required for the manufacture of rapid PCB prototyping. At present, the most common material is FR4, FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios.

Layers:The price of PCB board varies with the number of layers

Solder Mask: There are many colors about rapid PCB prototyping, green, black, white, blue, red, yellow, matt black and matt green (We support all of the above color). It is worth mentioning that considering efficiency and cost, UETPCBA regards green as a conventional color.

Silkscreen: The silkscreens printed on the PCB is usually matched with the solder mask color.

Copper:Generally according to the current of PCB circuit to scientific calculation of the thickness of copper, generally the thicker the better, but the cost will be higher, so it needs a reasonable balance (we support 1 to 10oz).

Via Process:Tenting vias, Plugged vias and Vias not covered

Surface Finish:Currently we support Electroless Nickel Immersion Gold (ENIG), Hot Air Solder Level (HASL, Lead and Lead‐free), OSP, Immersion Tin, Immersion Silver, ENEPIG Gold Fingers, Flash Gold, Full Body Hard Gold, Wire Bondable Gold, etc.

Quantity: The number of PCB prototypes to be made must be clearly stated.

Other Special Requirements: if there are any other special requirements for PCB manufacturing, you should also inform to your PCB manufacturer, like impedance control, custom stack-up and other special production process.

How to choose A Rapid PCB prototyping manufacturer?

When it comes to choosing a rapid PCB prototype manufacturer to outsource your printed circuit board (PCB) assembly services, there are some points to consider when deciding the best PCB prototype service:

The functionality of Manufacturing Equipment

The performance of this production equipment of a rapid PCB prototyping manufacturer is essential to their capacity to satisfy the contract’s requirements. Assessing their care logs may provide you the assurance that the business is serious about quality. This builds confidence in the company partnership.

Assembly Staff Obligations

To guarantee the PCB prototyping manufacturer may finish your manufacturing run on program demands not just well maintained, but also a certified team of meeting technicians. Thus, examine the certification and training documents of the meeting staff. Make sure they’ve got the specialized credentials to allow them to execute their assigned jobs. For all those staff members that aren’t certified, check out their progress from the certification procedure.

Quality Systems

Why does the meeting firm have an excellent system in place like ISO 9001:2008? This ought to be the minimal certificate attained by the enterprise to make certain they can provide an excellent product. When it’s another high-quality system set up, is your provider currently accredited by a licensed registrar? Eventually, would the PCB assembly manufacturer agree to spend in getting certified to the exact same excellent system as your own company? By doing that, it means that the organization is dedicated to some long-term business relationship with you.

Shipping Deadlines

Your capability to satisfy dispatch deadlines is a crucial metric that you establish whether a PCB prototype manufacturer has the capability, resources, and personnel to satisfy your company requirements. When possible, get records from the PCB manufacturer regarding their capacity to meet deadlines. Obtain a thorough comprehension of what is producing the PCBs and at which they’re produced.

Parts Procurement

Conduct an overview of the procurement section. Can they maintain a decent in-house stock? Are there sellers regional, local, or even geographically diverse, and what’s the character of these vendor relationships? Are the connections close enough that price discounts can readily be passed to you personally? How can their procurement division deal with hard-to-find or obsolete pieces? Do they’ve procurement experts who have experience in sourcing replacement parts for obsolete components? Can they choose your schematics/drawings and produce a Bill of Materials with very little if any help from you?

Economical Pricing

Since labor rates change, you should get an itemized breakdown of the whole cost of PCB manufacturing. Confirm what’s contained in the production expenses. Then you need to run a cost comparison analysis to establish whether their prices have been commensurate with the market average and their opponents.

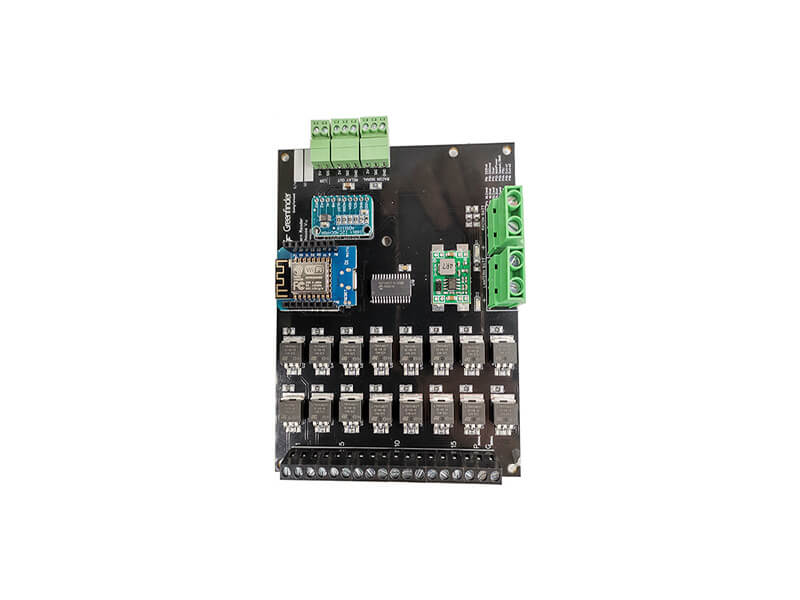

About UETPCBA

From ideas to reality, UETPCBA offers full-service PCB assembly manufacturing from prototype to short-run volume production. Whether you need quick turn printed circuit board assemblies, or need a rapid PCB prototyping, we are here to help our customer to prepare cost-effective and rapid pcb prototype for PCB fabrication or PCB assembly.