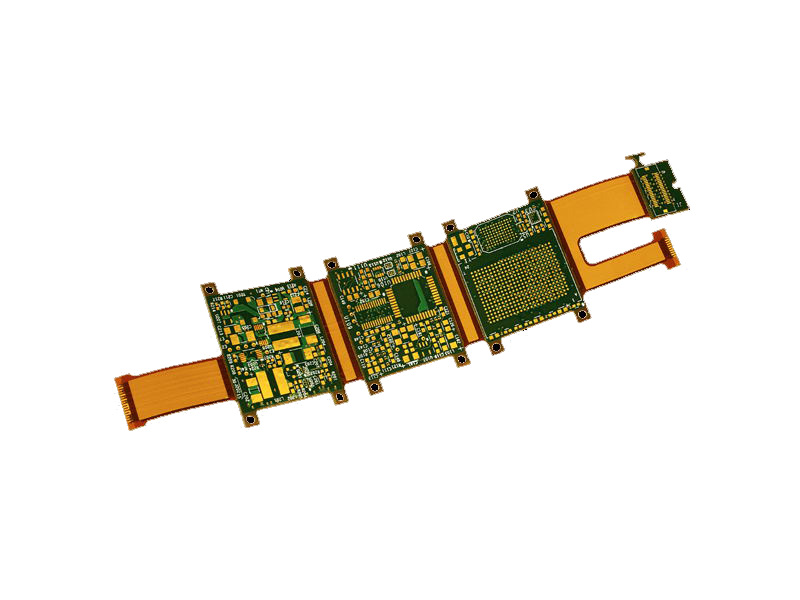

Flex and Rigid-flex PCB Assembly

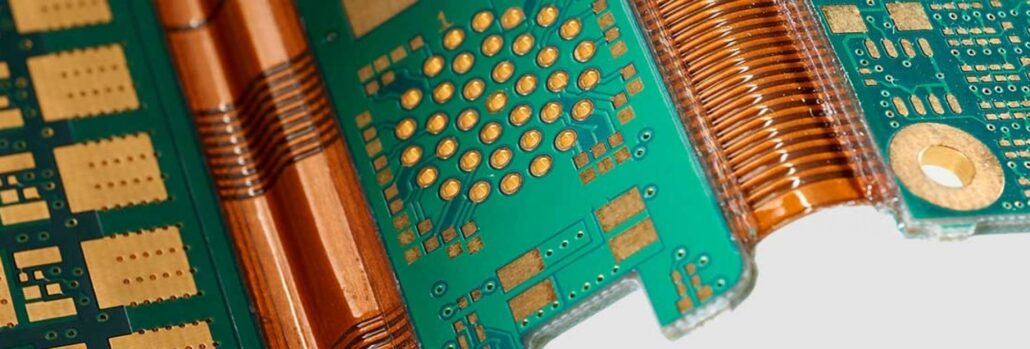

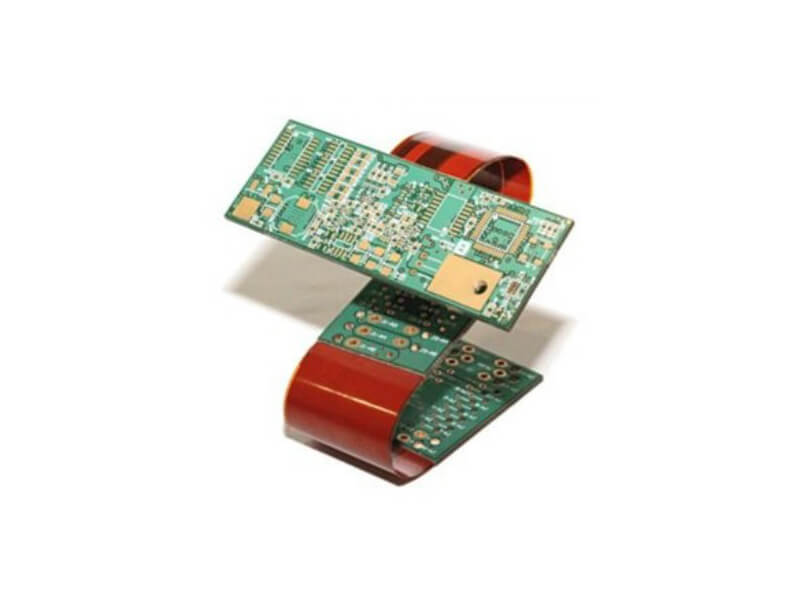

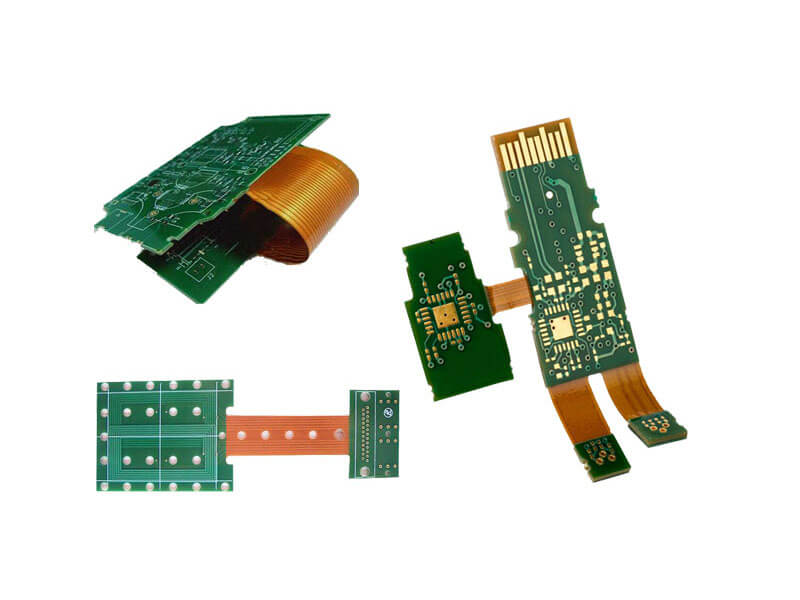

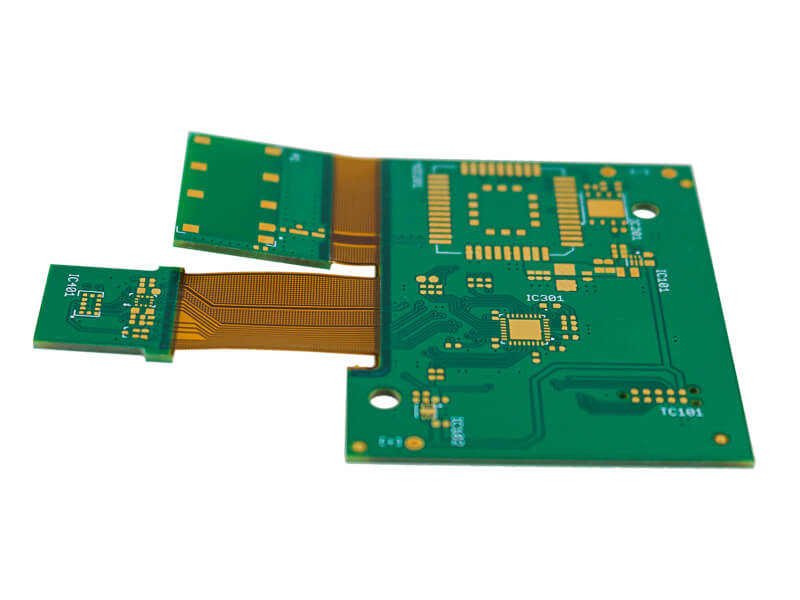

Flexible circuit technology provides a method to integrate multiple PCB assemblies, eliminate wires, cables or connectors, replacing them with flexible substrate between rigid sections. Flexible/Rigid-Flex printed circuit boards are lightweight, thin, flexible, compact, and easy to install, so they are widely used in a range of high reliability industries including Aerospace, Defense, Communication Electronics, Consumer Electronics) etc.

Cost of flexible/rigid-flex PCB fabrication and assembly are higher than regular rigid PCBs. And the assembly of flexible PCB is different from the rigid PCB in the assembly process.

As a professional flex pcb manufacturer, UETPCBA provides complete flexible/rigid-flex PCB fabrication and assembly services to meet all your turnkey PCB assembly requirements.

Are you looking for a high-quality flex and rigid-flex PCB Assembly manufacturer partner? Contact us,we’ll help you out.

Upload your data to receive an instant quote for fabrication, assembly and component options.

Experience our expertise and feel the difference.