Overview

Choosing a turnkey pcb manufacturing company for your project might wind up being a difficult undertaking. But, there are ways that you can use to restrict your choices.

When you’re on the market for a turnkey pcb assembly manufacture to supply your turnkey pcb assembly, then you want to know about several important problems. A few of the things you want to variable in include their manufacturing abilities, customer service listing, flexibility and responsiveness, and quality criteria, to mention but some.

What is turnkey pcb assembly?

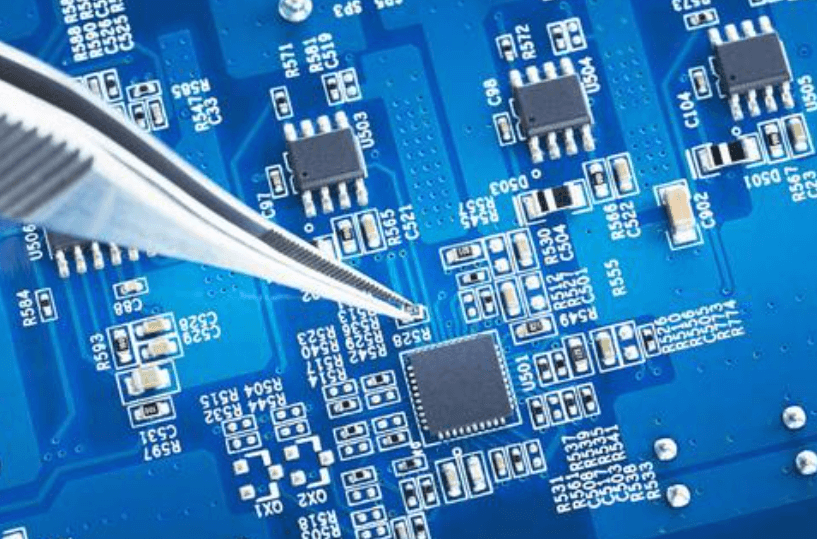

Turnkey pcb assembly means that pcbway turnkey company will handle all aspects of turnkey pcb, including component procurement and PCB manufacturing, picking and placing components in specific locations on the custom PCB. In this way, the full turnkey assembly service gives us more time and energy to focus on PCB design, while the pcbway turnkey company handles the rest of the work, which is why turnkey assembly is so popular.

Assemblers can attain the positioning of elements either manually or automatically. Turnkey pcb assembly is your ideal choice based on its precision and accuracy. As a professional and experienced turnkey pcb assembly company, UETPCBA will help you achieve full turnkey assembly services.

PCB Assembly Form

A complete Turnkey PCB Assembly includes creating the required services, which goes beyond PCBA. Electronics designers in many regions of the globe have a tendency to encounter challenges in receiving their prototype boards ready for use and testing. Because of this, PCB assembly solutions and technology are a requirement for them. With the ideal meeting and technologies, it is likely to produce high-quality PCBs that may be desired. Now, we’ll briefly highlight many Turnkey pcb assembly solutions and technology.

1. SMT Assembly (Surface Mount Technology)

A process where electrical parts become mounted directly on a PCB’s surface. SMT parts are usually PCBs face each than through-hole counterparts based in their brief leads.

2. Mechanical Assembly

Mechanical construction of PCBs involves placing together PCB elements in an assembly line. Furthermore, in addition, it describes assembled parts or products made this way. It is placing products with each other to execute a particular function.

3. BGA Assembly (Ball Grid Array)

Ball Grid Array, also referred to as BGA in summary, is just another surface mount technology bundle. IC, with lots of hooks, mainly utilize this kind of technology. BGA is a cheap packaging and high-density method that are perfect for bringing out some of the greatest circuit boards because of precision element positioning.

4. Cable Assembly

A cable assembly is a set of wires or wires organized into one unit. Largely, cable assembly may transmit electricity. Additionally, cable assemblies are used for delivering informational signs and supply electricity to a number of wires while coordinating them in a bundle that is simpler to replace and maintain.

5. Axial Horizontal Assembly

Axial results do protrude from each end of cylindrical or box-shaped parts. Axial-leaded elements do resemble cable jumpers concerning shape. They are primarily utilized to length short distances onto a PCB. Axial horizontal assembly comes in 2 configurations: right-angle through-hole and surface-mount. This leads do come in the other ends of this part.

6. Turnkey Assembly

That a Turnkey identifies some good or service ready for instant use by the individual buying it. Once applied to PCB meeting, the provider gets to deal with the printed circuit board job’s basic facets. It features parts/components procurement along with the production of a PCB.

7. Radial Vertical Meeting

Radial vertical assembly entails putting parts on a bare PCB hen the board area is limited. Here, the arrangement of parts is completed vertical on the printed circuit board. When speaking of vertical meeting, leads do come in 1 end of this component.

8. Box-Build Assembly

The box-build assembly also goes by the title systems integration. Box construct community is an entire Turnkey pcb assembly of the client’s finished product. The box identifies some PCB meeting in a cupboard that is filled with cables, a little enclosure, or a totally integrated electromechanical system with electronics and pneumatics.

9. Lead-free soldering

In commercial usage, lead-free solders may comprise silver, tin, aluminum, bismuth, zinc, indium, antimony, and other metallic traces. Lead-free soldering is the practice of soldering by employing lead. But, it is important to be aware that soldering with hints may produce dust and fumes which might be satisfactorily hazardous.

10. Printing

PCB printing describes shifting the design and PCB schematics on glossy or picture paper for ultimate generation. For the best outcome, the printing output has to be in the kind of a shiny side. Printing is a important step in the production of a PCB. Once done wrong, the results could be catastrophic.

11. N2 System

N2 describes a molecule of nitrogen gas. Nitrogen is a colorless and odorless gas which finds a great deal of usage in the production of PCBs. N2 process is using nitrogen gas using Turnkey pcb assembly, such as reflow soldering and selective soldering. N2 unique way of preventing oxidation issues and convection reflow.

12. Varnishing

Varnish coating applied to the surface of the printed circuit board. The most important intent is to safeguard the board and all of its components from corrosion and damage from the outside atmosphere. Varnishes assist PCBs to withstand harsh environmental conditions.

13. Testing

Printed circuit board testing is a vital step in the production of PCBs. With evaluations, producers can detect mistakes and rectify them. In this manner, they will be avoiding extra costs that include the requirement to perform reworks. With evaluations, there is a detection of mistakes that might lead to the board to malfunction.

14. Packaging

Printed circuit boards need to withstand physical breakage and also be from moisture. Inadequate packaging is a thing that might influence the appropriate performance of this board. For better characteristics of a commission, decent packaging is indispensable. If you would like PCBs that will operate correctly, ensure that your maker utilizes appropriate packaging.

The Advantage of Full Turnkey Assembly

The obvious benefit is that through Turnkey PCB Assembly, companies can have more time to figure out design issues. There is no need to spend time and energy to find the best components, but also to go through a painful procurement process, and then the internal team has to assemble them skillfully.

Reduce costs

With Turnkey PCB Assembly, there is no additional cost for goods delivery, which means you can save a lot of money. If you have established a good cooperative relationship with pcbway turnkey company, you can get more favorable parts prices.

Effective management

If you establish cooperation with multiple suppliers at the same time, there will be many problems, such as language and time. With Turnkey PCB Assembly, you are much less likely to encounter communication problems. Moreover, you only need to contact one party, which makes communication more convenient.

Identify problems in time

The main advantage of Turnkey PCB Assembly is the ability to find potential problems before turnkey assembly of any product. Before the start of assembly, the assembler will check and identify any possible errors. If any errors are found, there is an opportunity to correct and avoid inappropriate circuit boards.

Conclusion

The above is the basic knowledge about turnkey pcb assembly. With the development of technology, turnkey pcb assembly will become more and more simplified. UETPCBA has rich experience in this area. When you choose us as your cooperative printed circuit board assembly company, you choose the partner who provides the best service. We will always keep in touch with you. if you have any questions, please feel free to consult us.