With many PCB manufacturers, choosing the most suitable PCB manufacturer could be tricky. PCB manufacturer have to have the ideal type of experience and expertise, and if you’re placing an order, you have to look at a number of the vital specifics.

Different types of PCB manufacturing

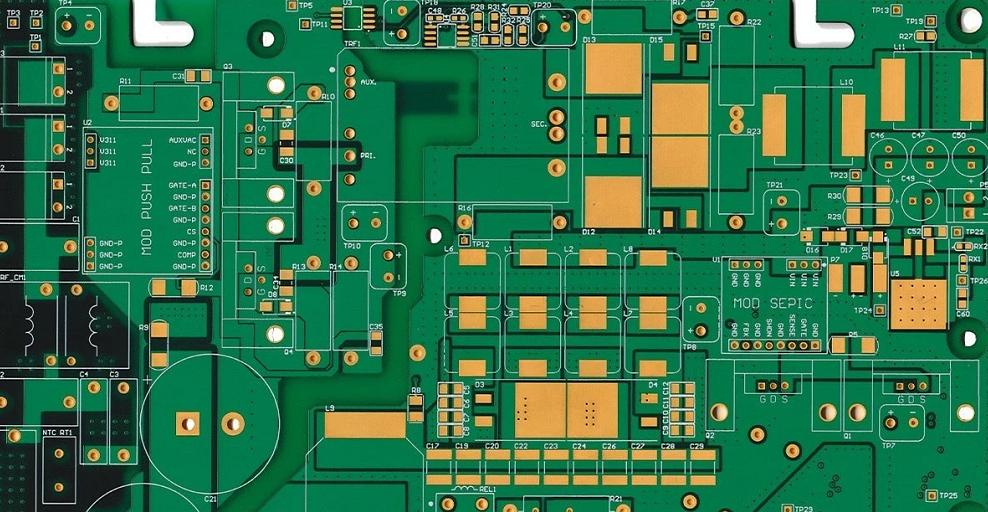

Frequently, the design and production of a printed circuit board (PCB) is as crucial as the layout of the major circuit itself. PCB manufacturers are increasingly using streamlined, flexible PCBs to build and organize digital circuits. A PCB could contain one or more insulating planks where copper layers and conductive sign traces have been etched or published. Based upon the complexity of the circuit, printed circuit board production could normally entail anywhere from one layer PCB to eight (or more) layers.This is a relatively big test for the professionalism of the printed circuit board manufacturer.

Kinds of PCBs based on layers

For those pcb board manufacturers with extremely basic circuits, then your PCB manufacturing will probably suggest the usage of a single-sided PCB. Here is the least complicated PCB of as the whole circuit-comprising the electric parts and the aluminum traces-is contained on a single insulating board.

A double-sided board retains a circuit that’s slightly more complicated than the usual single-sided board. As its name implies, either side of the substrate are used for home the circuitry elements. When manufacturing multilayer PCBs, pcb board suppliers often use through-hole technology.

Sophisticated pcb manufacturing and assembly is accomplished through multi-layered PCBs that contain many sheets of substrate with insulating material layers in between each. Based upon the intricacy of a circuit, such PCBs may vary from two layers to 4 layers to 8 layers, moving up to 42 layers in exceptionally complex circuitry.

Kinds of PCBs according to rigidity

Different applications require different kinds of PCBs. The pcb manufacturer will provide different kinds of pcbs. As an example, a rigid PCB is the most widespread and may be located in daily-use consumer electronics items such as televisions, computers, cellular phones and so forth. Such a plank, when flexed beyond a particular limit, will crack or split. Another common kind of PCBs which are made available by means of a PCB manufacturing is your flexible PCB. The circuits in this a PCB are constructed onto a thin, elastic insulating material. This permits the PCB to be curved and bent as desired without inducing harm to the circuit or the insulating material. You may observe flex PCBs used in medical equipment, flexible heaters, as well as equipment such as hearing aids.

The rigid-flex assortment of PCBs is a mix of flexible and rigid PCBs. These circuits are used in aerospace and military applications, in which a very compact circuit is necessary. The pcb manufacturer will attach great importance to this type of pcb. Rigid-flex PCBs save a large quantity of space, leading to digital products which weigh less.

Some PCB manufacturers can printed circuit board manufacturing may be performed for a limited number of circuits or to get large-volume production. It’s crucial to pick a PCB manufacturer with an established history.

7 Factors for Choosing a Reliable PCB manufacturer

By introducing the different types of PCB manufacturing above, we found that it is very important to choose a PCB manufacturer with a good reputation and high product quality. In this informative article, we’ve put together a list of hints that may come useful in locating the ideal PCB manufacturer.

1.Basic understanding of PCB manufacturer.

How long has the pcb fabrication firm been in operation? You have to understand a PCB board manufacturer inside out and how they do business in the business. If it comes to electronic equipment, expertise is a feature you can’t afford to take for granted. This relies on a reliable pcb manufacturer.

2.Can PCB manufacturer manage your needs?

This is only one of the primary questions that you want to inquire when you try to find a PCB manufacturer. Some pcb manufacturers just handle a typical set of specifications and tolerances, largely since their pcb manufacturing capabilities are restricted. If you’re searching for something very particular, you require a staff who will manage this.

3.Who are PCB manufacturer’s customers?

For PCB manufacturers, PCB manufacturing operates with numerous diverse customers in the electronics sector, and a number of them also take care of military orders. If you would like to learn a business better, you have to look at their clientele and the type of work they’ve done for many others. Having a trusted name, you do not need to be concerned about this particular aspect, because most of the information will be recorded on the website of the pcb manufacturer, and emerging companies will not mind sharing recommendation letters upon request., and also the emerging businesses will not mind sharing the testimonials on request.

4.Can PCB manufacturer provide engineering assistance?

That is one of those first questions, too. Before the actual cash is invested on the pcb manufacturing procedure, you want a business which is going to test all of the facets and will fully surrender to the requirements of their customer. They ought to examine the layouts, in order to prevent all probable mistakes in the long run. A fantastic pcb manufacturer will also spend much on improving their prospects and capacities.

5. PCB manufacturer Quality matters.

This really is a cliché thing to say, however in regards to PCBs, quality matters more than anything else. You do not to spend your funds on a pcb manufacturer who would not guarantee that ahead. Assess their functioning capacities and the type of jobs they could handle for your organization. If it comes to quality, you also should be aware of their testing procedure, particularly for connectivity.

6.When can PCB manufacturer provide?

But if you’re seeking to place a fast order, you have to look at this aspect, too. Most printed circuit board manufacturers need over a couple of weeks until they could deliver your order and that is not something you’d anticipate in the first location.

7.Can PCB manufacturer provide certificates?

Some PCB manufacturers provide” UL 94V-0 fire immunity certificate” on PCBs, and you might choose to check for additional applicable certifications, too. Simply speaking, the price you pay ought to be well worth the products that you get.

Ultimately, do inquire details of the sellers for content distribution. Together with PCBs, you must be really cautious about every facet. Take time to assess those facets, and you may always thank us afterwards.

UETPCBA is a professional pcb manufacturer, we can help customers make PCB boards, provides PCB prototyping and mass production. Our capabilities include Standard FR4/Roger PCB, Aluminum PCB, Flex PCB, Rigid-Flex PCB, HDI PCB and Copper base PCB, support Blind, Buried, Plugged Vias, Impedance control, custom stack-up PCB, etc. We are committed to providing cost-effective business solutions that optimize the performance of your products and exceed customer expectations.

Conclusion

The above is about several factors that you need to consider when choosing a PCB manufacturer. A reliable PCB manufacturer can save you a lot of time and energy. Many PCB manufacturers are available today. You only need to figure out your PCB needs and select the PCB manufacturer that can meet them satisfactorily.

If you are not sure of where to start, we are sure that some of the PCB manufacturerswe discussed above will give you a headstart of where to look at for your ultimate PCB needs satisfaction. UETPCBA has a pcb factory, which is a good choice for you to choose a pcb manufacturer.